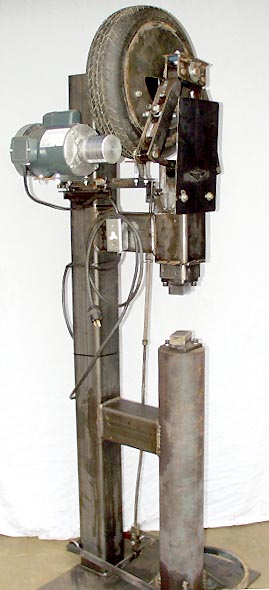

Tire Hammer

Ray Clontz Tire Hammer, designed by Clay Spencer

This is a power hammer for blacksmiths, bladesmiths, metal workers, fabrication shops, schools, copper smiths, hobby blacksmiths or anyone who needs a reasonable priced or build it yourself hammer with outstanding control to forge or shape hot metals.

Ray Clontz invented the concept of using a flat pulley driving a small diameter tire to power a blacksmith power hammer. He never built one but several other North Carolina blacksmiths built the hammers using Ray's concept with a spring cushioned mechanism similar to Little Giant.

As the motor is pivoted by the treadle, the flat pulley on the motor rubs against the rubber tire and drives the hammer. The low friction roller bearings of the axle and the slick UHMW plastic guide bearings guiding the hammer head allow this hammer to have exceptional control. A brake stops the hammer very quickly.

Now there are two versions of tire hammers: the original 50 lb hammer head with 300 lb. anvil and a version with 70 lb. solid hammer head, 500 lb. anvil, 1-½ hp motor and steel counterweight.

The original version of his hammer is a 50 lb. hammer with a 6" x 36" high solid anvil, either round or square, mounted on a 2' x 2' x 1/2" plate base. The rear column is 1/4" wall, 5" square tubing, 6' tall. It weighs 700 pounds and is just under 7' tall. It uses lead in the 4" square hammer head and also for the counterbalance weight. The hammer head guides are ultra high molecular weight polyethylene (UHMW), a very durable and low friction plastic.

The hammer runs about 250 rpm (depending on tire diameter) and uses flat dies made from heat treated 4140 tool steel.

This is a basic, reliable, durable, simple power hammer design using the time proven Little Giant spring mechanism. It does not have many adjustments – only the pulley – brake clearance, spring tension, treadle turnbuckle, shims behind the guide bearings and tire pressure. A 50 pound hammer is normally rated to handle up to 1" square stock. You can get 3" high stock between the dies and forge it very slowly and inefficiently.

The plans show flat dies so you can use tools with the hammer . You can make drawing dies and quickly change the dies using the 2 socket head screws (1/2"-13) on each die. Another option for smoother drawing is to make a spring fuller with half round die sections. If you are working with small stock it would be advantageous to add a ½" thick spacer under the bottom die (and longer screws). This allows the dies to touch together at a slower hammer speed where you have better control and are not so likely to smash the small stock.

The hammer is assembled by welding and some bolting. A little lathe/milling machine work is required on the parts that require precise fitting. A few jigs are a big help. The hammer is easy to maintain and repair if necessary.

You can find videos of hammers working by searching Google or YouTube for Tire Hammer or Clay Spencer tire hammer. More info on Facebook at

ClaySpencertirehammerUser'sGroup.

Raymond Head, Wetumpka, AL, e.m.forge@gmail.com, builds and sells the original design hammers. He also will sell you parts.

The heavier version with 70 lb. solid hammer head, 500 lb. anvil, 1-½ hp motor, different crank plate and steel counterweight uses most of the same parts with the above exceptions. It weighs over 1000 lb. No lead is used and the tire may be easily unbolted from the frame.